Digital twins and AI are tackling biopharma’s biggest manufacturing challenges

Digital twins and AI are tackling biopharma’s biggest manufacturing challenges

Biopharma manufacturers are facing mounting challenges, including rising complexity, data overload, scalability issues, and growing demands for speed and sustainability. To navigate this environment, companies are turning to digital twins and Artificial Intelligence (AI). Digital twins allow for real-time analysis and iterative simulation of manufacturing processes, while AI agents go a step further, executing tasks, designing 3D models, and automating the decision-making process. These tools work together to reduce manual bottlenecks, improve resource management, and transform massive data streams into actionable insights. As companies seek to future-proof their operations, the integration of AI and digital twins is quickly becoming a strategic imperative.

The pressures and challenges facing biopharma today

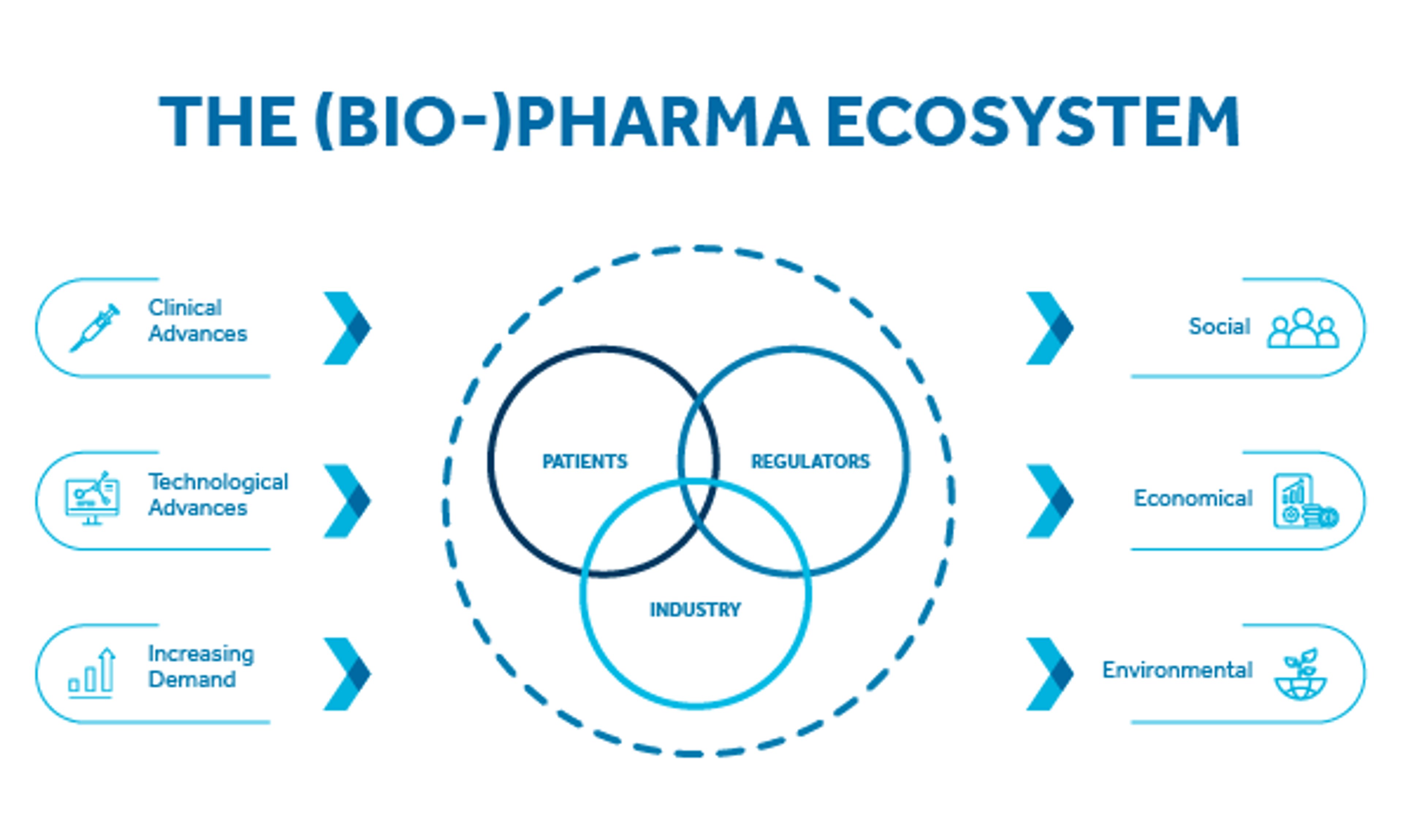

The biopharma ecosystem, made up of patients, industry, and regulators, faces numerous challenges that demand innovative solutions and fast decisions.

Emerging clinical advances like gene therapy and personalized medicine are transforming treatments. At the same time, technological progress is introducing new demands on infrastructure, data management, and scalability. That rising global demand, in turn, is then creating pressure on the production and distribution systems. On top of all that, the industry even faces growing societal expectations for equity, access, and transparency, while needing to balance innovation and cost.

Why companies are integrating digital twins and AI

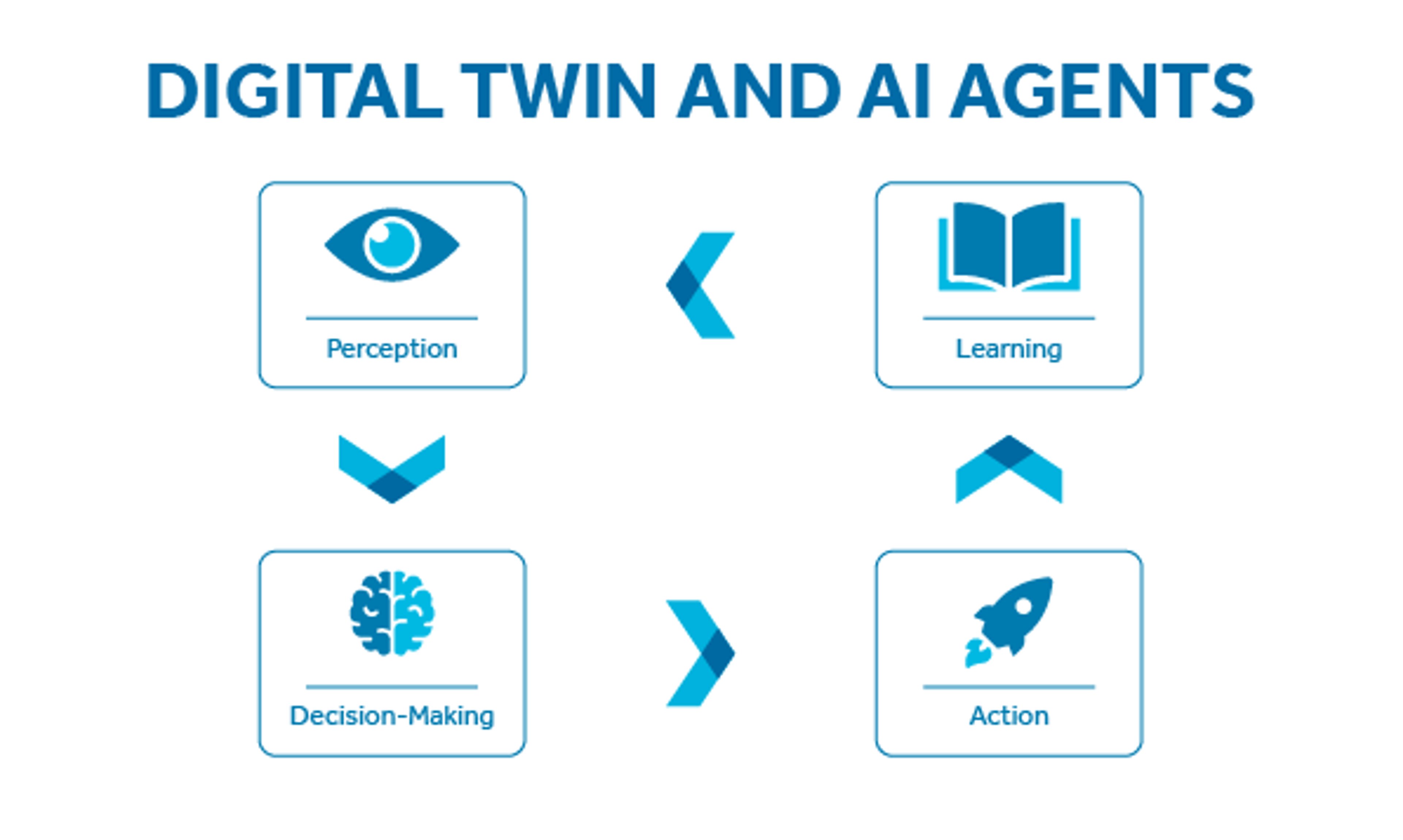

Two technologies standout for their potential to address these challenges: digital twins and AI agents.

Digital twins offer powerful ways to analyze and interpret operational data in real time, enabling simulations and optimizations that once required time-consuming manual work. AI agents take this to the next level by using AI to not only understand the tasks, but to execute them. In this way, they act as collaborative partners across the manufacturing lifecycle.

Automating the complexity of digital twin development

The convergence of advanced technologies offers transformative potential for streamlining the development and management of digital twins – a critical capability in today’s data-driven industrial landscape.

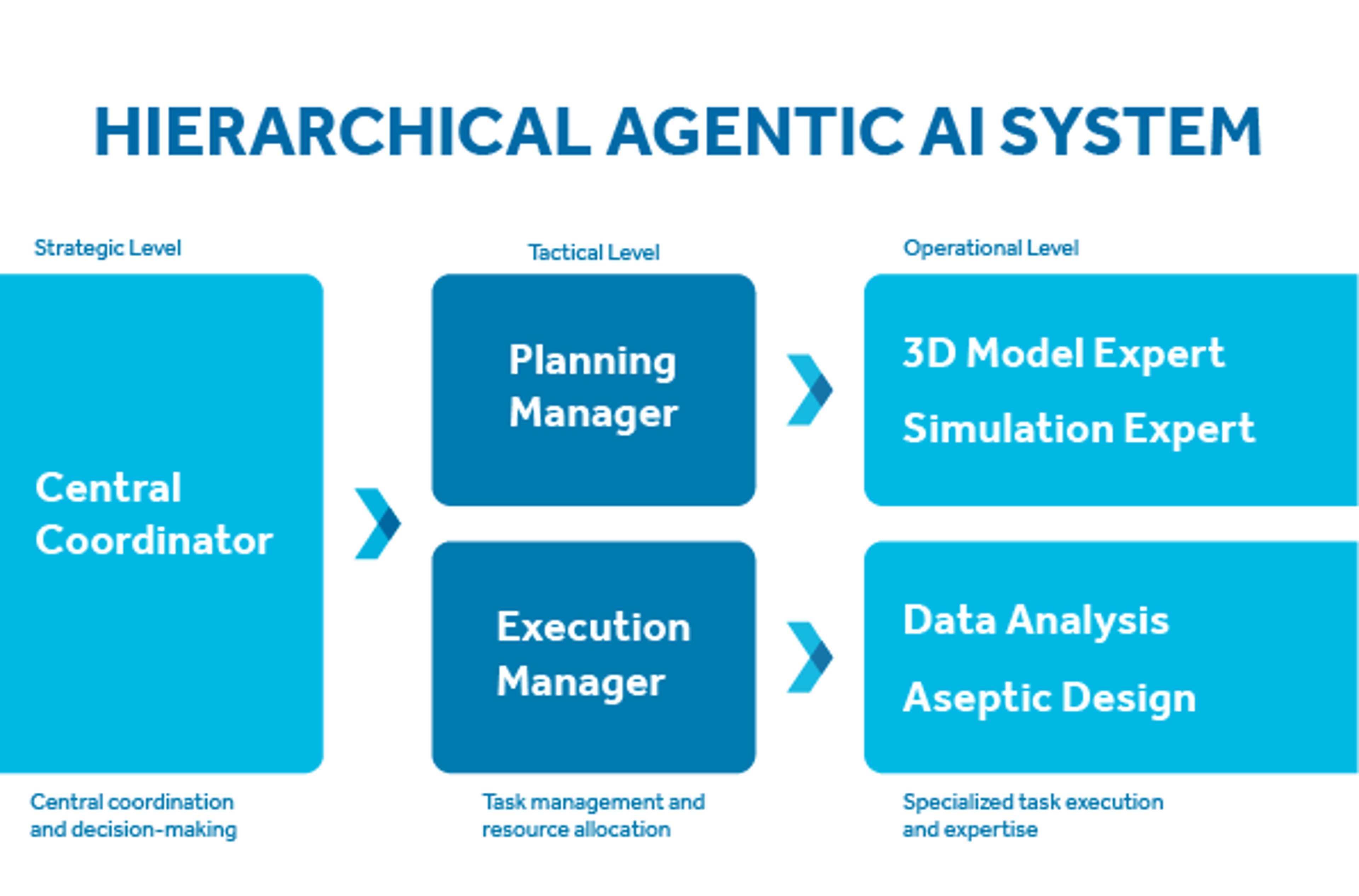

By integrating AI-driven automation with collaborative human expertise, organizations can significantly reduce the operational complexity involved in creating and operating digital models. Challenges such as constructing intricate 3D renderings, executing resource-intensive simulations, and managing vast streams of data are no longer issues. Instead, AI agents act as cross-functional teams, augmenting human efforts to execute tasks ranging from model design and simulation orchestration to network configuration.

Real-Time optimization in biopharma operations

This synergy becomes even more impactful in real-world biopharmaceutical applications. Once deployed, these AI-enhanced teams continuously monitor and optimize digital twins in real time, transforming them into dynamic tools for process refinement. The result is an intelligent ecosystem capable of aggregating, analyzing, and contextualizing massive datasets to generate actionable insights. Decision makers are empowered to act with unprecedented speed and precision – whether optimizing production workflows, mitigating risks, or accelerating innovation cycles.

Bridging human and machine for strategic agility

By combining human ingenuity with scalable AI automation, organizations can unlock a dual advantage: operational efficiency and strategic agility. In tightly regulated industries like biopharma, where margins for error are slim and compliance is non-negotiable, this integration is not just beneficial –it’s essential.

This approach future-proofs operations and positions enterprises to lead in an era defined by data-centric decision-making.

Advanced tools powering engineering and optimization

AI advancements like Text2CAD – which transforms text into precise 3D models – and large language models (LLMs) are revolutionizing engineering and biopharma operations. By integrating LLMs with tools such as ERP systems, businesses automate workflows, run simulations, and optimize decisions at scale.

These technologies bridge data silos and enable real-time resource management and predictive insights. In biopharma, this helps accelerate drug development and risk analysis. In engineering, it slashes design timelines and ensures compliance. Text2CAD further reduces errors and streamlines prototyping.

A clear competitive advantage

The result? A measurable competitive edge through faster innovation, cost efficiency, and agile responses to market demands.

For leaders, adopting these AI-driven tools is no longer optional – it’s imperative to future-proof operations, reduce time-to-market, and lead in an era of intelligent automation.

From vision to action

At Exyte, we don’t just imagine the future – we engineer it. By transforming cutting-edge innovation into actionable solutions, we empower industries, elevate communities, and redefine what’s possible.

Connect with our team to learn how we can help you transform challenges into opportunities and ensure your projects are ready for the coming future. Together, let’s chart a path toward innovation and excellence.