Luca Mussati explains ExyCell®

Luca Mussati explains ExyCell®

Luca Mussati, Vice President Technology Biopharma and Life Sciences at Exyte, tells us more about ExyCell®’s origins and prospects.

What is ExyCell and what is special about it?

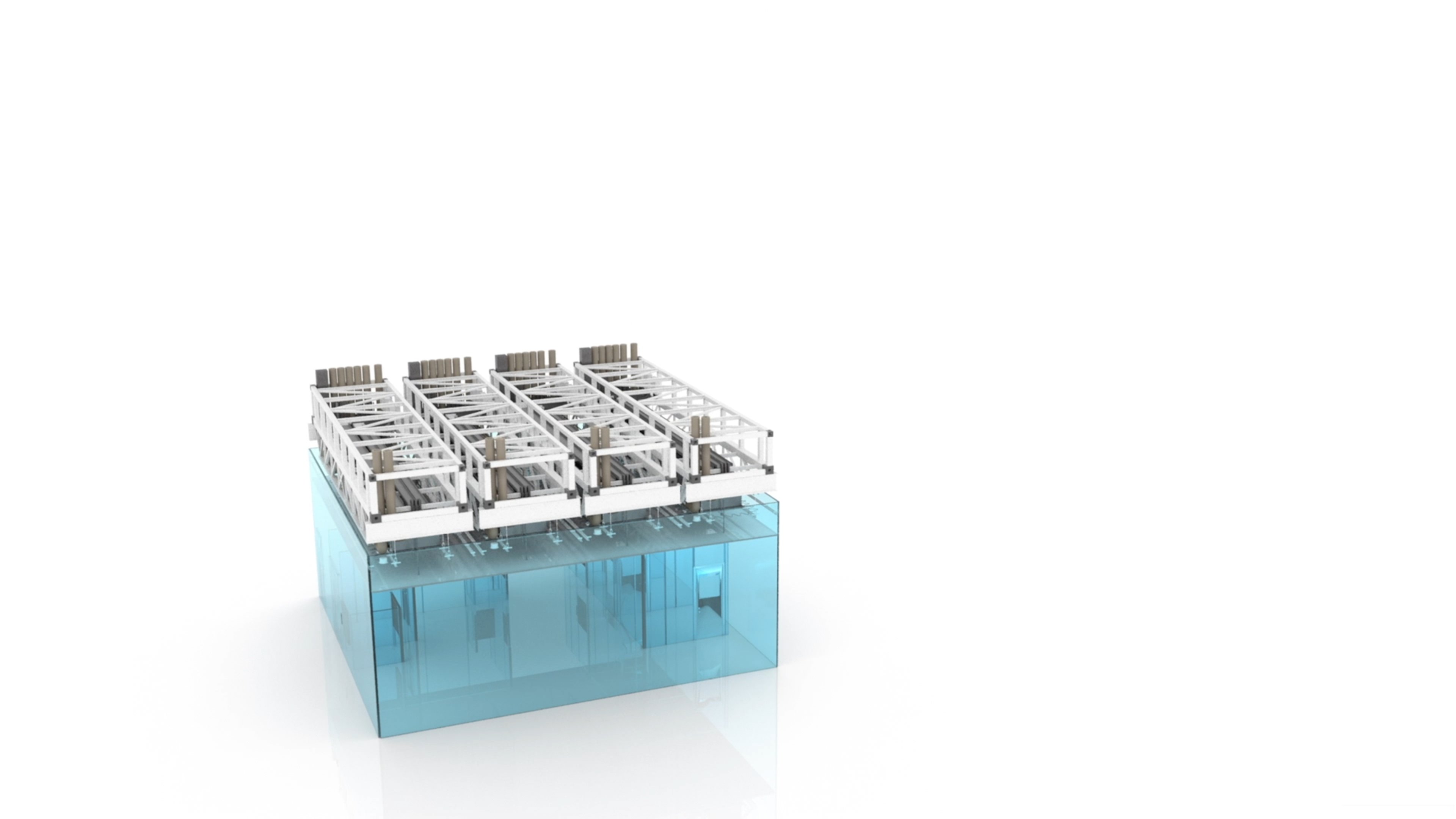

ExyCell is a prefabricated cleanroom solution for pharma manufacturing. Standardized and modular, its layout readily adapts to the given use case.

What exactly do you mean by modular?

We’re talking about a pre-engineered, prefabricated set of seven standard construction cells. These are modular mix-and-match components. ExyCell®’s layout consists of a standard 60-by-60 cm grid pattern that can be varied at will to assemble any desired cleanroom. Each cell comes with the piping, heating, ventilation and air conditioning (HVAC), cabling, sensors, and everything else needed for a functional cleanroom.

Which industries stand to benefit from ExyCell?

We offer ExyCell® to the pharma and biotech industry – that is, companies that make drugs, vaccines, monoclonal antibodies (mAbs), messenger ribonucleic acid (mRNA), and other products for cell and gene therapy, viral vectors, personalized medicine, and the like. We aim to branch out and offer ExyCell® cleanrooms to other sectors that make medical devices, food and beverages, semiconductors, and other products in controlled environments.

Why does modularity matter to an engineering company?

Modularity paired with standardization and off-site manufacturing means fewer hours spent at the drawing board and building on site. That spares resources and boosts quality and safety. But the greatest advantage is speed. A modular approach with paralleled on-site construction and off-site manufacturing can cut clients’ time to market by as much as 50 percent.

It does sound like a big departure from the norm. Can you tell us more about ExyCell®’s USPs? What sets it apart from the competition?

Our huge engineering experience flowed into ExyCell®. Its demand-driven design is rooted in clients’ needs. We want ExyCell® to be easy to understand and use, and so very flexible that it readily adapts to any process, layout, footprint, and height up to 5.5 meters. Each cell’s width matches that of a standard container, so ExyCell® is easy to ship – no fussing with special racks or custom pallets. And it accommodates any brand of pharma walls, doors, and windows, including floor-to-ceiling glass walls.

ExyCell® is an Exyte invention. How did you and your team come up with the idea?

The program was born in August 2018 when 35 Exyte experts from around the world convened to compare notes and lessons learned from 20 years of modular delivery. The name ExyCell® is actually a nod to what we had in mind – a cellular concept. Rather than rehashing conventional modular solutions, we set out to revolutionize pharma facility design. Our efforts culminated in the cell, a simple self-contained brick that streamlines and accelerates construction. Even very complex structures go up very fast. You know what inspired us – a global flat-pack furniture giant’s kitchen sales model. This company lets you design your kitchen with an online configurator and instantly get a layout and price. So why were we reinventing the wheel for every project?

Tell us a little about your team. Who are they and what do they do?

The ExyCell® team is proudly international. We have colleagues from Germany, Switzerland, USA, India and Shanghai on board. Everyone is doing excellent work to enable our customers to make vital pharmaceutical products available faster than ever before. We are truly committed to create a better future and enhance the quality of modern life.

How is market acceptance so far? What’s next for ExyCell®?

ExyCell® has given rise to many alliances aimed to offer end-to-end, turnkey solutions. Siemens, Miltenyi Biotech, and Univercells worked with Exyte to integrate our products and create innovative facilities. Currently we are rolling out an online 3D layout tool. Its user-friendly drag-and-drop interface, virtual reality tools, and a big equipment database will enable any client to design a biopharma facility. Empowering the user to interact with designers in the early phases of a project – that’s a game-changer.

Excited to build a better future with us?

We offer a wide range of exciting projects where you can drive progress and make your mark.