Advanced Technology Facilities

Reducing the energy consumption of battery cell gigafactories

Advanced Technology Facilities

Reducing the energy consumption of battery cell gigafactories

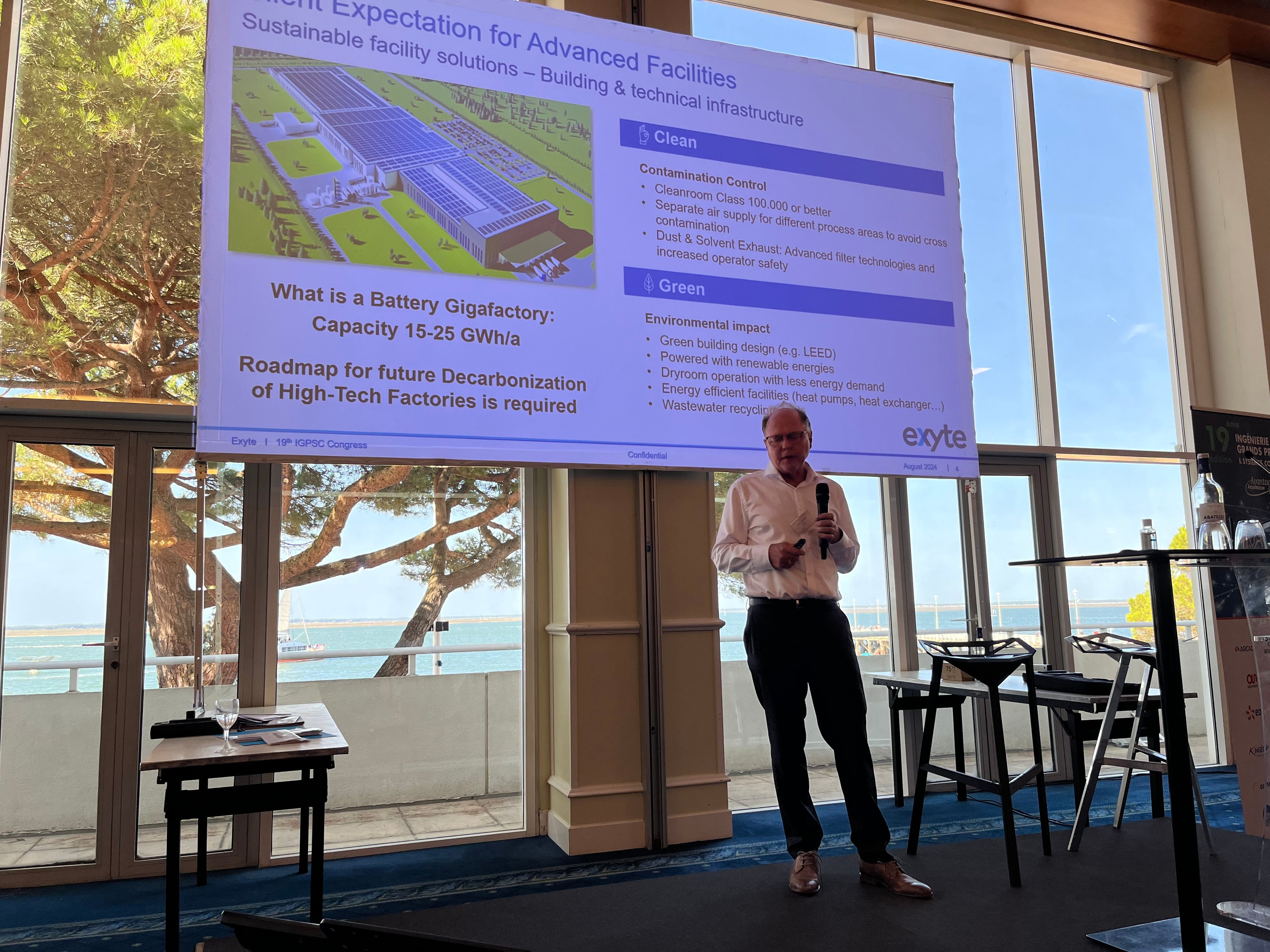

As the adoption of electric vehicles (EVs) and the demand for stationary storage and other energy applications continue to accelerate, the need for battery cells is rising sharply. Producing these cells involves intricate, energy-intensive processes that significantly contribute to the carbon footprint of manufacturing facilities. This is where Exyte comes in.

Exyte has a successful track-record of delivering world-class battery cell gigafactories. With a deep understanding of the manufacturing process, Exyte is uniquely positioned to offer innovative sustainability-in-design solutions that effectively mitigate environmental impacts.

Dr. Klaus Eberhardt

Exyte’s Senior Director Global Technology Management for Battery, outlines the way to decarbonize the battery value chain. “Profound understanding of the battery technology specifications and the technical infrastructure required to meet them, proper early planning, carbon sequestering, green procurement, and Off-Site Manufacturing (OSM) are some of the means to help reduce the carbon emission during construction, but there’s more,” Eberhardt says.

The key to sustainable battery cell production

The largest carbon emission is derived during the plant operation and the key to reducing it lies with the facility planning and design – long before construction begins. Eberhardt encourages battery manufacturers to consider the accessibility of renewable energy supply and a stable grid when selecting a site for their new gigafactory. “Large battery cell manufacturers have, for example, chosen locations with large solar, hydroelectric or wind power capabilities in the region, allowing their facilities to operate to a large extent on renewable energy,” Eberhardt says.

Optimizing design to reduce energy consumption

Additionally, methodical and proficient design and engineering of the facility can further reduce the energy usage, for instance, by optimizing the design of the dry room. A dry room is the facility’s centerpiece where the moisture content in the air is carefully regulated to ensure the safe and high-quality production of the lithium-ion (Li-ion) batteries. Maintaining this controlled environment is essential in battery cell manufacturing to avoid moisture-related problems that could affect safety, quality, and overall production yield.

The dry room has a high cost of investment and uses approximately 25 percent of the energy required to operate a battery cell gigafactory. Behind the coating and drying processes, the dry room is the second largest consumer of the facility’s energy demand. By utilizing smart energy systems this can be reduced by up to 50 percent. “Exyte has developed energy efficient concepts to enable this’”, Eberhardt explains.

The energy footprint of the Dry Air Handling Units (DHUs) can be lowered. These pieces of equipment ensure that air is kept at an extremely low humidity level, is circulated and conditioned, and temperature and cleanliness are tightly controlled. Reducing their energy usage while increasing operator safety can be achieved by recirculating the exhaust air from process tools in the slitting or assembly area, through optimized particle control systems, and energy-efficient designs.

Planning sustainability from the design

Eberhardt underlines the importance of EPC (Engineering, Procurement, and Construction) companies, like Exyte, in determining the sustainability of a gigafactory. “When sustainability measures are considered in the facility’s design before it is built, a larger carbon footprint reduction can be achieved and at a significantly lower cost than if they are implemented in a fully operating facility. An integrated design-build approach is key to reach this target”.

Get in touch with our experts to find out more about Exyte’s sustainable battery cell manufacturing solutions and what other developments such as microenvironments will play a role in the near future.